Container dismantling refers to the careful separation of a prefabricated structure into smaller components to facilitate transportation, relocation, or repurposing. This process is typically carried out when a project is completed, or when there is a need to move, renovate, or re-equip the container. Unlike complete demolition, dismantling allows for the recovery and reuse of parts at a new site or project.

This feature is one of the main advantages of prefabricated structures such as containers. At the end of construction projects, components can be dismantled and reused elsewhere, preventing waste of resources.

Which Containers Can Be Dismantled?

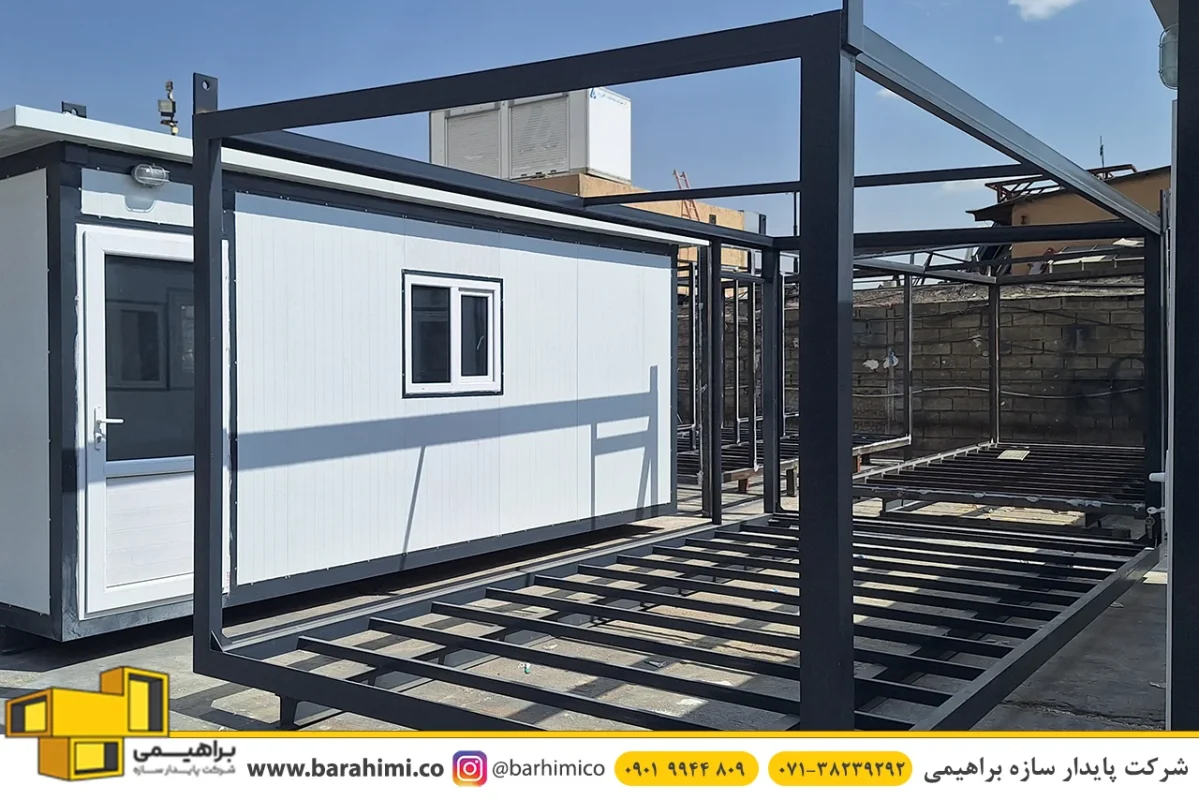

Bolt-and-nut containers:

Built with bolted frames instead of welding, these units are easy to disassemble and reassemble. They require less time and cost, making them ideal for temporary uses such as project offices, mobile administrative spaces, or small workshops.

Welded containers:

These offer greater strength and a seamless look, but dismantling requires cutting welded joints. The process is time-consuming, requires specialized tools and expertise, and components often need re-welding or replacement connectors upon reassembly.

Special containers (wooden or composite):

Due to their design and materials, dismantling requires greater care. Some parts may need reinforcement, repair, or replacement during reinstallation.

Ultimately, dismantling feasibility depends on the design, materials, and construction method of the container.

Steps in Container Dismantling

Initial inspection: BarahimiCo experts visit the site to assess structure type, condition of joints or welds, environmental factors, and infrastructure. A dismantling plan is prepared.

Removal of internal systems: Electrical wiring, plumbing, HVAC, and other systems are disconnected and secured to prevent damage.

Separation of non-structural components: Wall cladding, flooring, roofing, and exterior finishes (wood, sandwich panels, etc.) are removed and packaged separately.

Frame dismantling:

Bolt-and-nut containers: bolts are unscrewed and components separated.

Welded containers: joints are cut with specialized tools and frame sections are divided into transportable parts.

Packaging & loading: Parts are secured in pallets or crates and loaded onto trucks or trailers. Heavy sections may require cranes or flat-pack handling.

Transport to new site or storage: Components are safely delivered for reuse or storage.

Reassembly at new location: Containers are reinstalled per original plans or redesigned layouts as needed.

Key Considerations

Safety: Disconnect all utilities (power, gas) before work begins.

Component check: Inspect all parts before transport; repair or replace damaged items.

Material planning: Ensure extra bolts, screws, or connectors are available for reassembly.

Waste management: Recycle and minimize disposal of leftover materials.

Skilled labor: Always use experienced teams with the right tools.

Legal compliance: In urban areas or large projects, municipal or engineering permits may be required.

Cost Factors in Container Dismantling

Type of container: Bolt-and-nut, welded, or custom (wood/composite).

Size & complexity: Larger, more complex units cost more.

Installation site conditions: Difficult access or harsh environments increase costs.

Condition of the container: Repairs may add to cost.

Tools & manpower: Specialized cutting or crane use impacts pricing.

Transport costs: Packaging, loading, and delivery are included in the total cost.

Applications of Container Dismantling

Relocating offices, workshops, or accommodations after project completion.

Repurposing containers (e.g., from office use to sanitary or retail use).

Reselling or leasing second-hand containers while maintaining functionality.

Multi-project usage, especially in oil, mining, road construction, and civil engineering.

Efficient dismantling and reassembly reduce costs and speed up project timelines.

BarahimiCo: Modular & Portable Container Solutions

BarahimiCo specializes in custom modular and portable containers, designed with dismantling in mind. Our advantages:

Bolt-and-nut structures for easy dismantling and reassembly.

Professional teams with the right equipment for safe and efficient work.

Standardized packaging and safe transport with cranes, trucks, or flat-pack systems.

Pre- and post-process inspections to prevent damage.

Upgrade options for layout or functionality during reassembly.

With this approach, BarahimiCo supports temporary, long-term, or cyclical projects across various industries. Our services ensure that containers maintain original quality even after multiple assembly and dismantling cycles.

Why Professional Dismantling Matters

Untrained workers may damage components, increasing repair costs.

Using the wrong tools risks damaging internal systems or infrastructure.

Poor packaging or unsafe transport creates safety and financial risks.

Overlooking details can shorten the container’s lifespan and increase unforeseen expenses.

Types of Containers Commonly Dismantled

Workshop & project camp containers – most frequently moved after construction projects.

Mobile office containers – for temporary administrative needs.

Villa or commercial containers (beach, wooden finish, etc.) – dismantled for relocation or redesign.

Public service containers (toilets, guard posts, kiosks) – transferable between projects.

Redesign After Dismantling

Once dismantled, containers can be redesigned internally—adding partitions, windows, or functional spaces. At BarahimiCo, this is a priority. We provide consultation and design support to remodel containers to meet updated needs.

Containers built with dry construction materials (sandwich panels, PVC cladding, modular flooring) are easier to dismantle. Modular designs allow multiple reassemblies without structural damage. BarahimiCo incorporates these features into its custom builds, using lightweight, durable, and recyclable materials to ensure both functionality and ease of dismantling.

Dismantling in Harsh Environments

Some projects require dismantling in remote, extreme, or hazardous locations, such as deserts, mountains, or industrial zones. Challenges include:

Specialized equipment for sandy or rocky terrain.

Strict safety compliance in industrial zones (refineries, hazardous areas).

Complex transport logistics requiring cranes or even helicopter lifts.

BarahimiCo’s experienced teams and specialized equipment make us a trusted partner for projects in such demanding conditions.

Dismantling for International Projects

With the growth of cross-border projects in oil, gas, renewable energy, road construction, and disaster relief, demand for easily dismantled and transportable structures has risen. International projects often require prefabricated structures to be exported or relocated in dismantled (flat-pack) form due to customs and shipping requirements.

BarahimiCo designs containers to meet international transport standards, ensuring cost-effective and compact packaging for overseas projects. This capability has made us a reliable partner in many regional and international ventures.